In Fertigungswerkstätten denken viele Menschen sofort an Schweißroboter und Handhabungsroboter,

Aber es gibt eine Art von Ausrüstung, die oft übersehen wird —— Roboter-Polier-/Schleifeinheiten. Sie sind nicht wie Schweißen, aber tragen stillschweigend das Schlüsselglied von "qualifizierten" zu "hochwertigen" Produkten.

Dingzhu Intelligent Equipment Co., Ltd. ist ein Pionier auf diesem Gebiet.

Warum brauchen wir Roboter zum Polieren?

In traditionellen Fabriken basieren Schleifen und Polieren oft auf manueller Bedienung. Langfristige Exposition gegenüber Staub und Lärm schafft nicht nur eine raue Umgebung, sondern führt auch zu geringer Effizienz und instabiler Qualität.

Mit der steigenden Nachfrage nach Präzision, Aussehen und Konsistenz von Teilen auf dem Markt sind die Einschränkungen des manuellen Polierens immer deutlicher geworden

Begrenzte Effizienz: Es ist schwierig, eine stabile Produktionskapazität über einen langen Zeitraum durch manuelles Polieren aufrechtzuerhalten.

Schlechte Konsistenz: Unterschiedliche Arbeiter und Schichten weisen erhebliche Unterschiede in der Effektivität auf.

Sicherheitsrisiken: Staub, Lärm und scharfe Kanten stellen alle eine Bedrohung für die Gesundheit der Arbeiter dar.

An diesem Punktwird die Roboter-Polier-Einheitzu einer idealen Alternativlösung.

Die Kernkompetenz der Roboter-Polier-Einheit

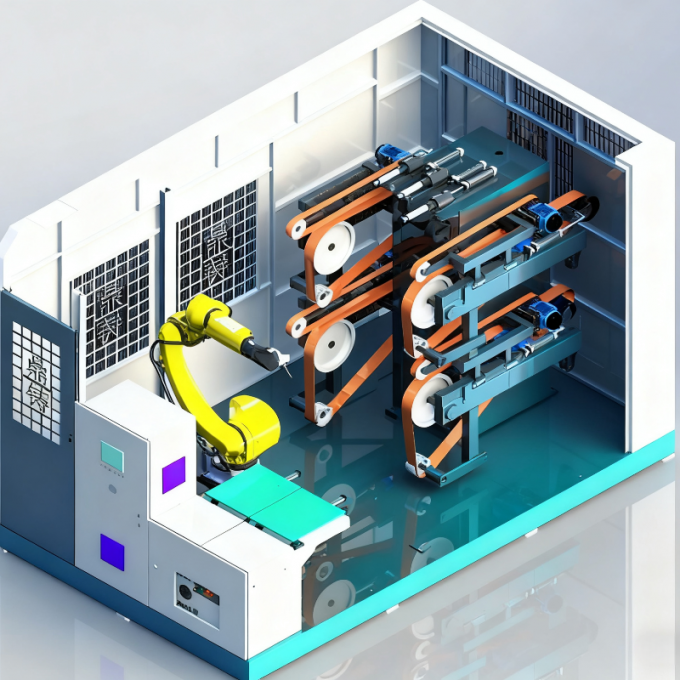

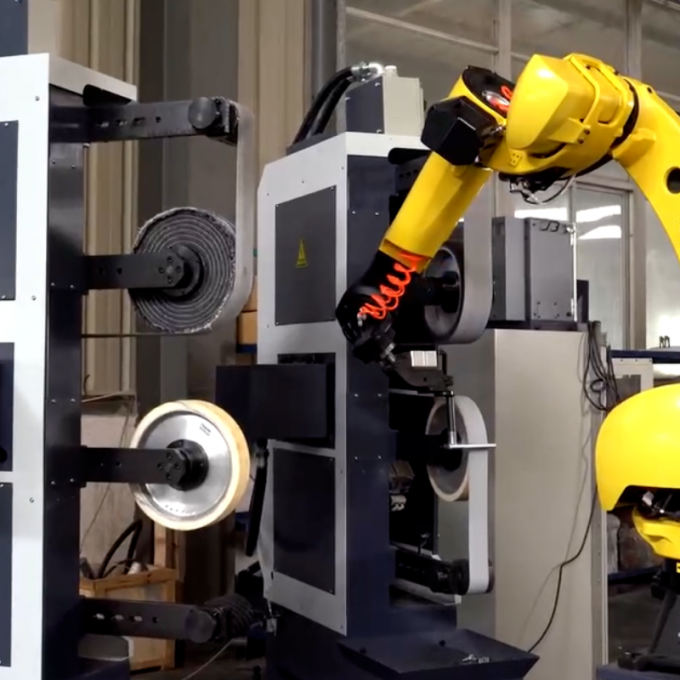

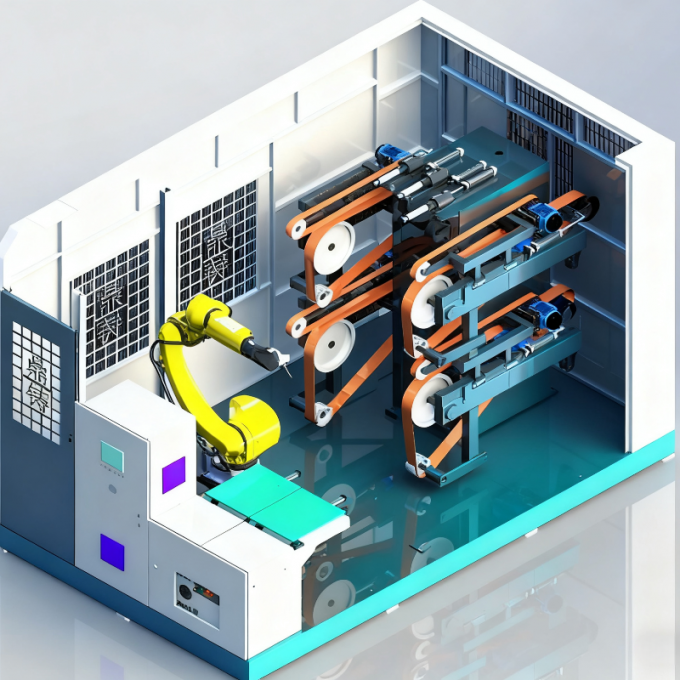

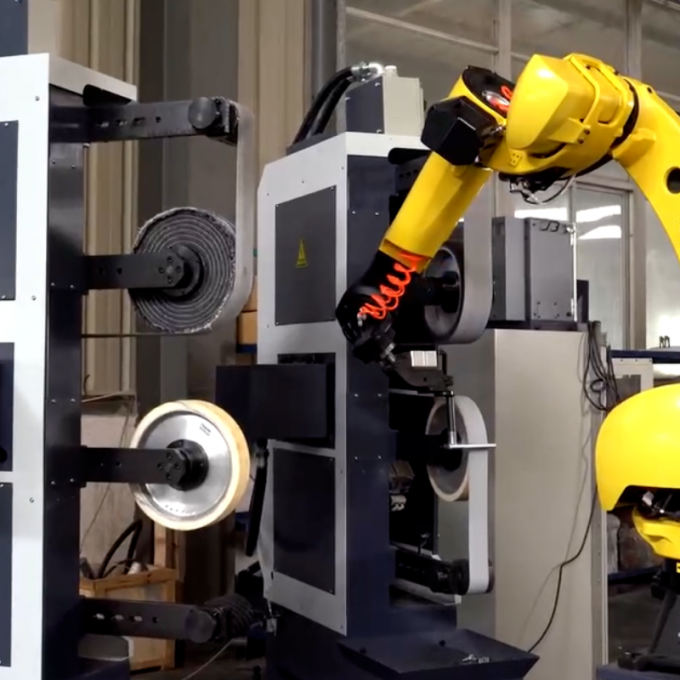

Die Roboter-Polier-Einheit von Dingzhu Intelligent Equipment kombiniert im WesentlichenIndustrieroboter mit professionellen Polier-/Schleifwerkzeugenum eine stabile Verarbeitung durch ein Automatisierungssystem zu erreichen.

Präzise Kraftkontrolle: Echtzeit-Erfassung des Drucks, ohne "Über-Schleifen" oder "Unter-Schleifen".

Hohe Konsistenz: Die Oberflächenglätte von Hunderten von Werkstücken ist nahezu identisch.

Verdoppelte Effizienz: 24-Stunden-Dauerbetrieb mit einer Produktionskapazität, die um ein Vielfaches höher ist als bei manueller Arbeit.

Flexible Verarbeitung: geeignet für verschiedene Materialien wie Gusseisen, Aluminiumlegierung, Kupferteile usw., auch für komplexe Oberflächen.

Sicherheit und Umweltschutz: Reduzierung der manuellen Exposition gegenüber Staubumgebung, Unterstützung der Staubabsaugung und des Not-Aus-Schutzes.

Machen Sie Produkte raffinierter, Fabriken effizienter und die Umwelt sicherer.

Wo kann es angewendet werden?

Nachbearbeitung von Gussteilen: Entgraten, Schleifen des Angusses, um die Kanten der Teile glatt und nicht schädlich für die Hände zu machen.

Automobilkomponenten: wie Räder und Zierteile, müssen Haltbarkeit und Aussehen in Einklang bringen.

Hardware- und Dekorationskomponenten: Wasserhähne, Türgriffe usw. Polieren bestimmt das Gefühl der Wertigkeit.

Formenbau: Die Oberflächenglätte von Formen beeinflusst direkt die Qualität der Produkte.

Eine einzelne Robotereinheit kanndie Produktionskapazität um das 2-3-fache erhöhen, wobei der Oberflächenfehler innerhalb von± 0,01 mmkontrolliert wird, was in der Branche ein hohes Niveau darstellt.

Zukünftige Entwicklungstrends

Obwohl die Roboter-Poliertechnologie ausgereift ist, entwickelt sie sich weiter:

KI-gestützt: Vision + Algorithmus, beurteilt automatisch den Zustand des Werkstücks und passt die Parameter an.

Flexibles Werkzeug: Das Ende ist leichter und flexibler, geeignet für komplexe Teile.

Grüne Fertigung: Reduzierung von Staub und Energieverbrauch, im Einklang mit Umwelttrends.

Vollprozessautomatisierung: Integration von Be- und Entladen, Polieren und Reinigen, um eine unbemannte Produktion zu erreichen.

Die Roboter-Polier-Einheit ist kein optionaler Schritt,

aber es ist ein wichtiger Schritt in Richtung Verfeinerung und Intelligenz von Industrieprodukten. Dingzhu Intelligent Equipment hilft mit seiner Erfahrung und technologischen Akkumulation mehr Fertigungsunternehmen dabei,Doppelte Verbesserung von Qualität und Effizienz. Auf dem Weg der "Bewegung in Richtung Neuheit" in der Fertigungsindustrie,

spielen diese 'unsichtbaren Meister' eine immer wichtigere Rolle.

Xiamen Dingzhu Intelligent Equipment Co., Ltd.

WhatsApp/WeChat:+86 17859772836

WeChat:+86 18850546401

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!